What is Laser Cleaning

Laser cleaning is a technology that uses focused laser light to remove unwanted substances, such as dirt, rust, paint, or contaminants, from surfaces. Laser cleaning leverages the interaction between a high-energy laser beam and matching the energy threshold of only the material to be removed, vaporizing it and turning it into gas. High powered laser provides the versatility from non-abrasive, delicate cleaning right up to highly aggressive, providing 50+ micron surface profiling on steel without the need for sandblasting. This technology is safe and helping move our world toward a greener environment.

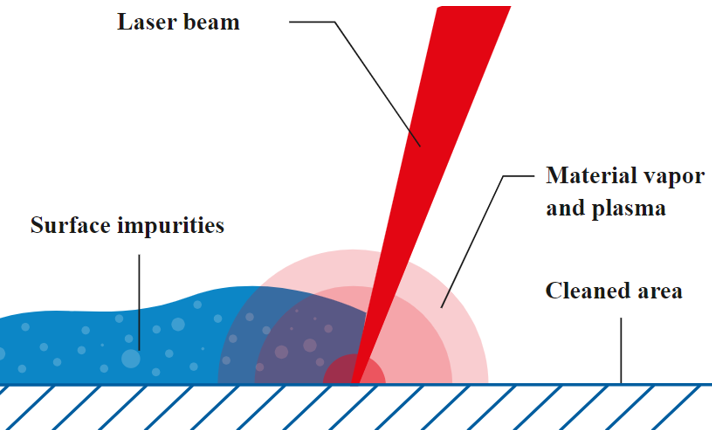

How laser technology works

Ever heard the phrase clean disruption? Think – film to digital camera, landline to mobile. Modern industry demands that we find ways to do things; smarter, faster and better than before. Whilst traditional methods still have their place and application, Laser is a rapidly evolving technology that is breaking into many industry sectors due to its benefits, versatility and accuracy. How it works in very simple terms.

1. A high-energy laser source shoots nano-second pulses of light at the surface contaminants to be cleaned / removed

2. The laser it tuned by the operator to the frequency of the contaminant that is to be removed

3. The contaminants (not the substrate) absorb the laser energy, which causes them to instantly vaporize or break free of the substrate.

4. Gases and any small loose particle are captured via a fume extraction system. Any particulate is captured for disposal and the air is filter through multiple HEPA filters providing > 99.9% clean air

Benefits

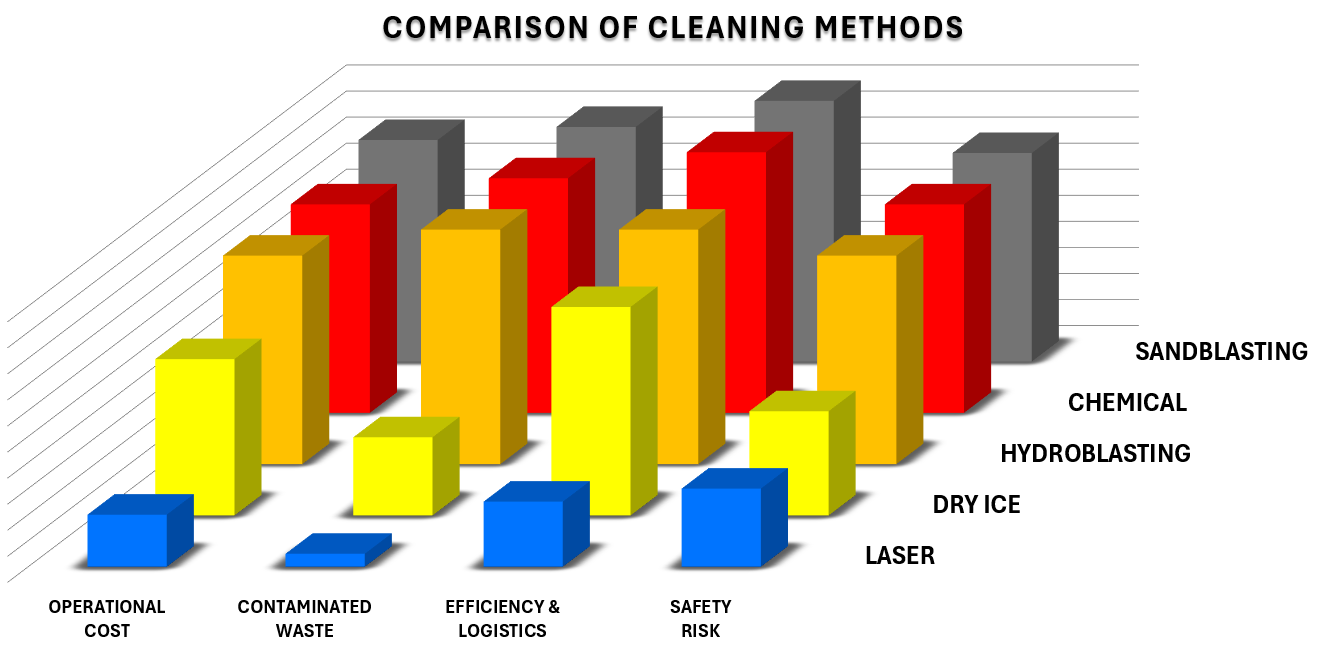

Operational Cost -30%

Due to the versatility, mobility and speed, Laser is the ultimate solution saving you time and money. Laser can resurrect machined surfaces on components that would normally be disposed of. No large infrastructure investment such as scaffold and hoarding to enable works to commence. No consumables or media required. Get in, get done, get out.

Contaminated Waste – 99%

There are no airborne contaminants, smells or toxic waste. HEPA filtration purifies the fumes into clean breathable air.

The only contaminated waste is the small particulate ( < 1% ) that is not vapourised. This is caught in an auto-bagging system through the fume extraction system. No more hefty bills for contaminated waste disposal and you are saving the environment for our future generations.

Efficiency & Logistics – 50%

Laser mobilization to start of operation is very rapid. With the technology being very fast and accurate, the job can be done before others strike a blow. All it needs is 3 phase power.

Dip Laser is a fully mobile service provider. The machine is 250kg, has certified integrated lift points, measures 1m x 1m x 0.5m. It has a 30-meter working radius reach be it vertical in an EWP, or down the hole in a confined space.

Safety Risks – Low

No blast pressure injuries, no eye injuries from flying debris, no chemical burns or chemical spill risks.

Our lasers are operated by trained and competent professionals. We will always provide a Laser Safety Officer for the job. They come with all required PPE, Equipment, Safe Work Procedures and complete an “On the job” Risk Assessment, specific for the scope that day, or when the conditions change throughout the day.

Industries we work in

Our Service

✓ Off-site facility in Mackay for laser cleaning of your smaller components. < 2000 kg and 3 cubic meters

✓ Off-site facilities can be sourced for large components.

✓ Fully mobile mine compliant LV & Trailer

✓ G2 & S123

✓ On-costed equipment hire at your request, or you can supply

Laser Tech

✓ 3 Kw Laser

✓ 30m working radius from machine

✓ 415v 32 amp 3 Phase power required

✓ Beam Width: 10mm- 200mm

✓ Scan Profiles: 8 types

✓ Frequency Adjustment Range: 0.1 – 20,000 Hz

✓ Power Range Adjustment: 10 – 100%

✓ Ambient Working Temp: 0°C – 42°C

✓ Ambient Working Humidity: 10% – 95%

✓ Substrate Profile Capacity: Variable 0 micron to >50 microns

✓ SAE 2.5 Cleanliness

Evolve your business …. call ours !

Contact

Ryan De Paoli I 0407 237 646 I Ryan@diplaser.com.au I ABN: 80 681 855 792 I MACKAY

Contact

Ryan De Paoli I 0407 237 646 I Ryan@diplaser.com.au I ABN: 80 681 855 792 I MACKAY